TOP-DOWN CONSTRUCTION TECHNOLOGIES by [FS] Foundation Specialists, Inc.

An example of Top Down Construction is the Construction of the Five Stand Tandem Cold Mill of the National Steel Corporation, Designed and Constructed by Foundation Specialists, Inc. in Iligan City, Mndanao, Philippines. The Five Stand Tandem Cold Mill is a Rolling Mill producing Cold Rolled Steel Plates in coils. The design of the Plant required the formation of a deep Pit for the foundations and installation of the Rolling Mill huge machineries supplied by BLONOX (US) for the COLD ROLLING of high precision steel plates in coils. The large, deep pit, located near the sea shore, on reclaimed land , and contiguous to newly built and fully operational plant, was designed by FS to be executed using TOP-DOWN Construction Technologies, to guarantee a short construction time and to avoid any disturbance to the adjacent, operating. NSC Plants. The Sequence of TOP-DOWN construction scheme was designed for simultaneous construction of Cast-In-Place Anchored Reinforced Concrete Diaphragm Wall [DW] with one meter thickness. The depth of DW was determined by the necessity to embed the bottom of DW into impervious strata of clay underlying the plant area, so that the impervious clay strata would serve as the BOTTOM PLUG of the Pit,

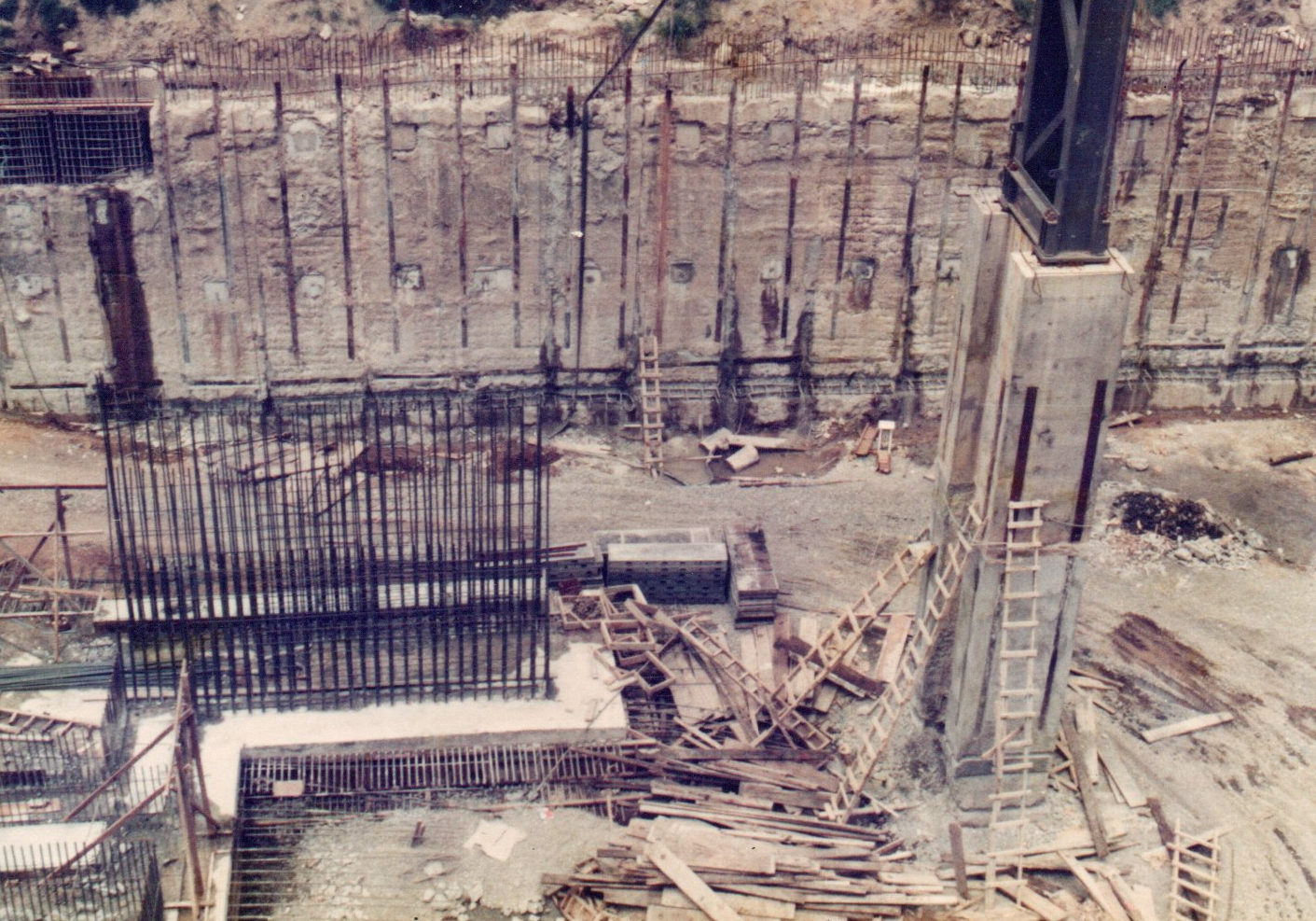

totally sealing the pit’s bottom against water seepage, [NOTE : FS design also provided the customary Sump Pits with Pumps, part of standard design of deep Pits, to remove seepage water, but in so many years since the time of construction, the pumps were never used, because the Pit has remained totally dry, as it was assumed at the time of DW Design with DW bottom’s embedment into the impervious Clay formation] , The DW was provided with steel plated, anchored to the reinforcing bars cages before installation into the excavated DW panels. The steel plates were designed to be exposed after the pit excavation, to serve as support for the pipes and cable racks to be attached to it. All of it is clearly visible in the attached pictures. The DW were designed to be built not only as permanent support of Pit’s excavation, but also to support the parimetral structures of the plant. Part of the TOP-DOWN Construction Scheme of the Five Stand Tandem Cold Mill Plant are the “H” shaped huge Pile-Columns provided to support the Gantry Cranes’ Runways and the

Roof Structure of the Plant. The “H” shaped Piles–Columns were built before the Pit’s excavation, by excavating, from NGL, deep Pile- Columns, formed by three DW Panels excavated, reinforced with "H" shaped Prefabricated Reinforcing Bars Cage, and cast with High Strength Concrete, monolithically, to form huge Pile- Columns with the proper axial and lateral capacity to support the Plant’s roof and the heavily loaded moving Gantry Cranes , high above the Pit's floor. The Top-Down Construction Scheme permitted to construct the Plant’s superstructures, including roof and gantry cranes, while excavation of the pit was still in progress, thus substantially cutting construction time and allowing the early commissioning of the whole Five Stand Tandem Steel Mill.